Beverage Plant Production Equipment

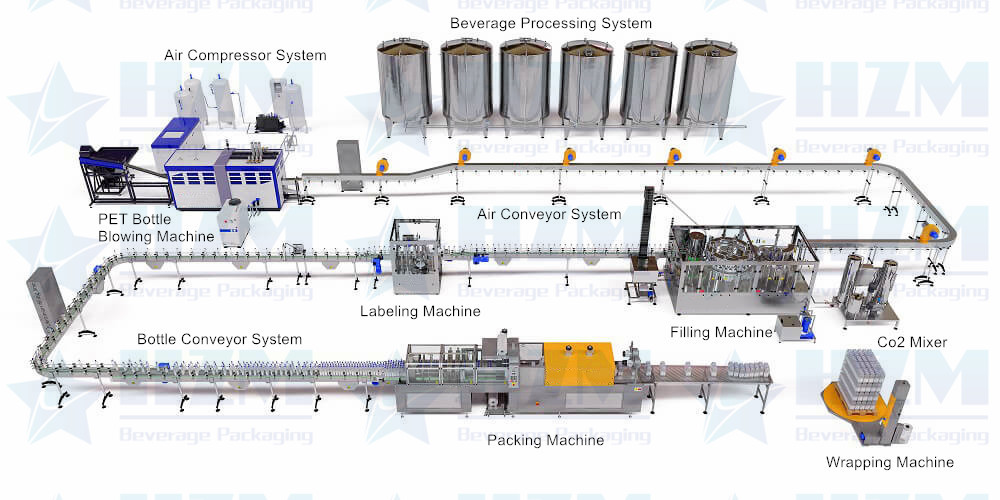

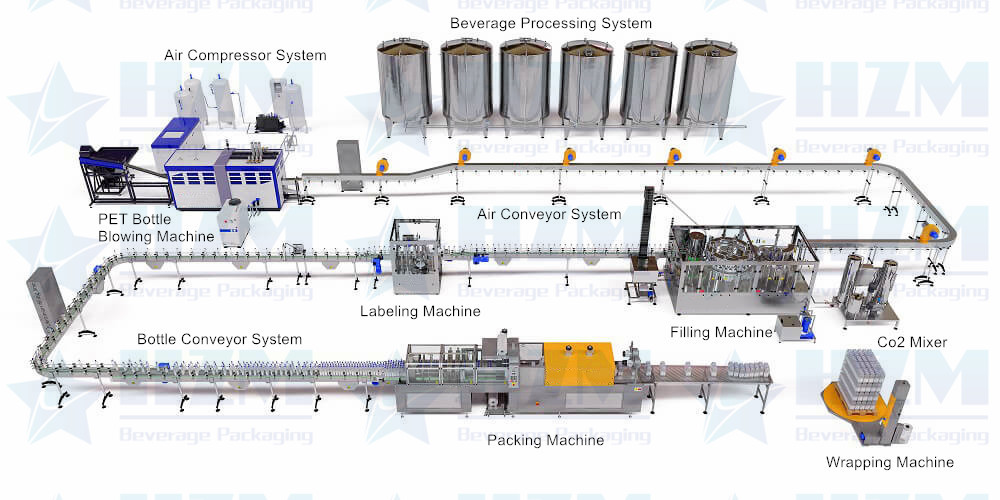

Beverage plant production equipment refers to the machinery and tools used in the manufacturing and packaging of various beverages, including soft drinks, juices, bottled water, beer, wine, and more. These machines play a critical role in the production process, ensuring that beverages are produced efficiently, safely, and with consistent quality. Here are some common types of equipment used in beverage production plants:

- Mixing and Blending Equipment:

- Tanks and agitators for mixing ingredients, such as water, sugar, flavorings, and additives.

- Homogenizers to ensure uniform particle size and consistency.

- Filtration Equipment:

- Filters and separators to remove impurities and particulates from the liquid.

- Pasteurization and Sterilization Equipment:

- Heat exchangers and pasteurizers to eliminate harmful microorganisms and extend shelf life.

- Filling and Packaging Equipment:

- Bottle fillers and cappers for filling bottles with the beverage.

- Can fillers and seaming machines for canned beverages.

- Labeling and packaging machines for applying labels, caps, and packaging materials.

- Bottling and Canning Lines:

- Complete lines that automate the process of filling, capping, and packaging bottles or cans.

- Carbonation Equipment:

- Carbonation systems to add carbon dioxide to soft drinks.

- Quality Control Equipment:

- Sensors and analyzers to monitor and ensure the quality of the product, including pH meters, density meters, and spectrophotometers.

- Beverage Pasteurization and Cooling Systems:

- Systems for heating and cooling beverages to specific temperatures for processing.

- Conveying Systems:

- Conveyor belts and systems for transporting containers throughout the production line.

- Beverage Tanks and Storage:

- Storage tanks for holding raw materials and finished products.

- Cleaning and Sanitization Equipment:

- Cleaning-in-place (CIP) systems to clean and sanitize the equipment.

- Utilities and Infrastructure:

- Refrigeration systems to maintain product temperature.

- Boiler systems for generating steam.

- Water treatment and purification systems.

- Automation and Control Systems:

- Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs) for process control and monitoring.

- Bottling and Packaging Inspection Equipment:

- Equipment for inspecting the filled bottles or cans for defects or contaminants.

- Palletizing and Material Handling Equipment:

- Machinery for stacking and moving pallets of finished products.

- Waste Treatment and Recycling Systems:

- Systems for managing and recycling waste materials generated during the production process.

Beverage production plants may vary in size and complexity, so the specific equipment used can differ based on the type of beverage being produced and the production capacity of the facility.

HZM Machinery is your premier partner in the field of Beverage Plant Production Equipment. As a professional manufacturer, we are committed to providing high-quality and high-efficiency equipment to meet your production needs. Our innovative technology, stringent quality control, and extensive experience enable us to tailor solutions for various types of beverage production. Whether you are producing soft drinks, juices, beer, wine, or other beverages, HZM Machinery will provide you with reliable equipment to achieve efficient production and exceptional quality. Choose HZM Machinery for a successful partnership.

TAG: Beverage Packaging Machine Carbonated Drinks Filling Machine

-

![Core Selling Points of Glass Bottle CSD Filling & Capping Line]()

Core Selling Points of Glass Bottle CSD Filling & Capping Line

-

![Customizable beverage filling system]()

Customizable beverage filling system

-

![Differences Between Hot Filling and Cold Filling in Beverage Filling Machines]()

Differences Between Hot Filling and Cold Filling in Beverage Filling Machines

-

![Selecting a Dedicated RO Reverse Osmosis Water Treatment System for a Purified Water Beverage Production Line]()

Selecting a Dedicated RO Reverse Osmosis Water Treatment System for a Purified Water Beverage Production Line

-

![How Fast Is the Labeling Speed of Tea Beverage Packaging Machines?]()

How Fast Is the Labeling Speed of Tea Beverage Packaging Machines?