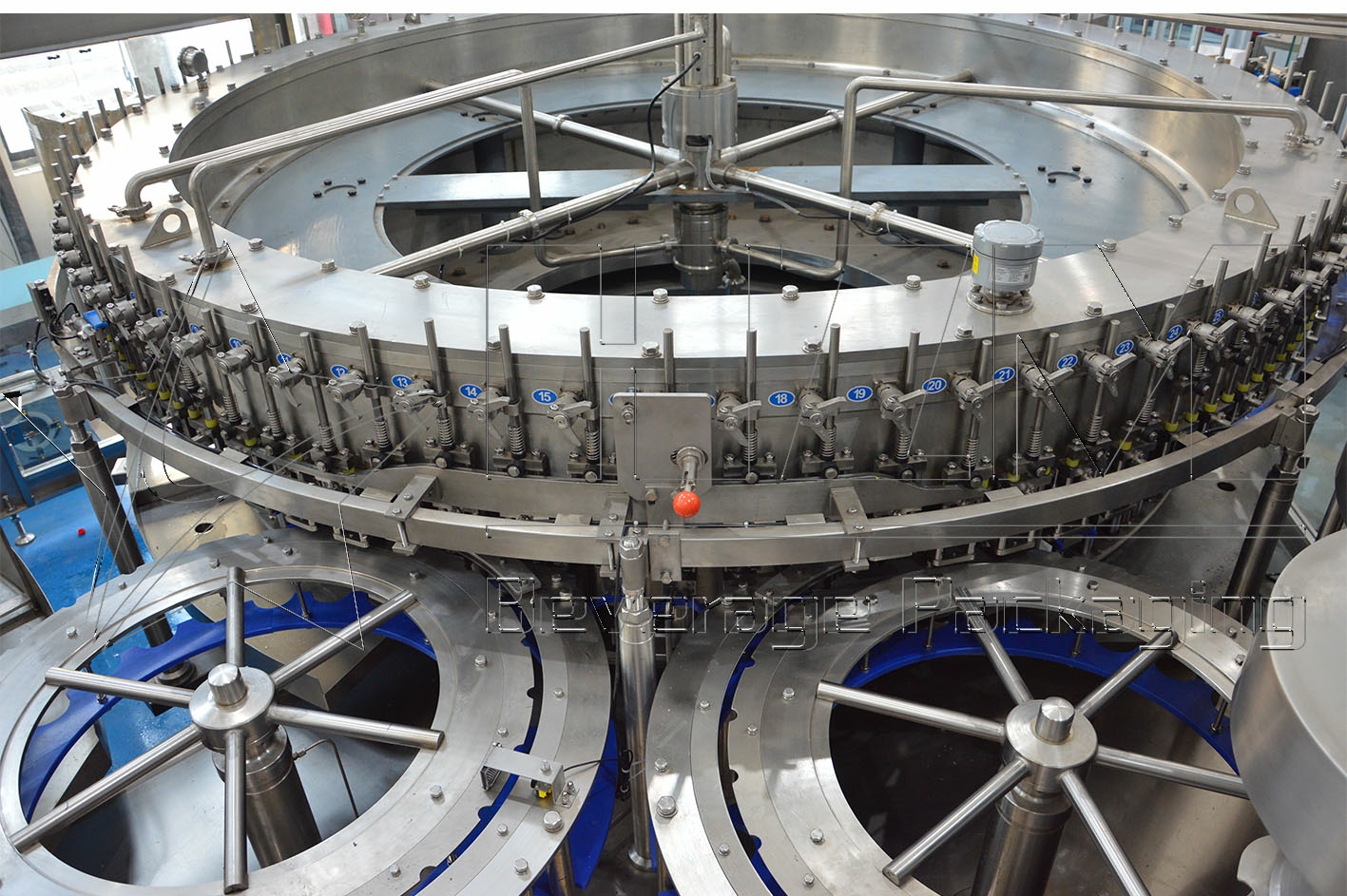

Beverage Industry Heavy Duty Automatic Conveyor System

| Material: | Stainless Steel | Place Of Origin: | LangFang, China |

|---|---|---|---|

| Certification: | GB/T19001-2000 | Type: | Filling Machine |

| Key Selling Points: | Long Service Life | Material Feature: | Heat Resistant |

| Structure: | Conveyor System | Application: | Filling Machine |

| Voltage: | 220/380V | Dimension(L*W*H): | Customized |

| High Light: | Heavy duty automatic conveyor system, Heavy duty auto conveyor system, 380V Automatic Conveyor System | ||

Beverage Industry Heavy Duty Automatic Conveyor System

Stainless Steel Full Automatic Air Conveyor System For Bottle Lines

Waterproof SS 304 material rack with SS304 bearing (please choose this type of rack and bearing when water transfers goods). Stainless steel frames are widely used for product transfer in the food and beverage industry.

The frame is curved without any gaps on the back. Can improve the service life of the conveyor.

The stainless steel filler strip under the belt protects the modular belt from running smoothly. And support the belt to run at high speed under high load. It can also reduce the coefficient of friction between the modular belt and the conveyor frame.

Specifications

|

Material |

Stainless steel |

|

Place of Origin |

LangFang, China |

|

Certification |

GB/T19001-2000 |

|

Type |

Filling Machine |

|

Key Selling Points |

Long Service Life |

|

Material Feature |

Heat Resistant |

|

Structure |

Conveyor System |

|

Application |

Filling Machine |

|

Voltage |

220/380V |

|

Dimension(L*W*H) |

Customized |

Main features:

1. Stable conveying, using synchronous chasing control between the conveying belt and engine, making bottles in good condition in the conveying: non-falling, non-block, non-jam. And the cushion platform can be set before labeling machine, when the label is changed , the filling machine can keep working , no need to stop and waiting. The filled product during this period will be stored by the cushion, when label changing is finished, labeling machine will label the stored product in a high speed , and producing speed recovered.

2. Conveying belt is designed by module, component can be interchanged easily, structure is compact, noise is little, easy assembling and maintaining, have flexibility to combine the bottle type according to the different capacity.

3. The design of electrical control is advanced and rational, we can design the control method , select the electrical control component according to client’s layout, to improve the conveying stablity

4. set the switch according to conveying system layout or customer reasonable requirement, for the convenience of operation.

Quality Control

To guarantee the excellent performance of our beverage production lines and beverage machinery, we introduce advanced technology from Germany and Italy, and constantly improve our production technology of liquid filling. Apart from that, free trainings are offered to our employees to help them improve technical skills. In addition, we strongly believe that beverage production lines and beverage machines with high pass rate and reliable quality can effectively reduce production cost. Thus, we strictly implement product inspection in every step of production, from raw material acquisition to shipping our finished products, to ensure the quality and pass rate. Besides, much attention is also placed on perfect management system and high quality employees for a higher working efficiency.

FAQ

Q: What are the Primary Products of Your Company?

A: Our products mainly include water production line, juice production line, tea production line, water filling machine, juice filling machine, tea filling machine, and more.

Q: Where is Your Beverage Machinery Applied to?

A: Our beverage production lines are extensively used for packaging of water, fruit juice, tea drinks, milk beverage, juice with grains, sodas, protein beverages, energy drinks, and more.

Q: What are the Properties of Your Beverage Production Lines?

A: Our beverage machinery adopts automatic operation system which greatly improves the performance and productivity of our packaging machines. They have properties of multifunction, standard design, modularization, digital control system, good compatibility, high accuracy, flexibility, and high working efficiency.

All these measures together enable us to provide high quality carbonated beverage production lines, can filling machines, juice production lines, tea filling machines, etc, at competitive prices.

Q: Do Your Water Production Lines Meet Environmental Protection Requirements?

A: Our water production lines are eco-friendly and energy-saving. They adopt advanced environmental protection technologies from Germany and Italy. All production procedures quite meet the standards of ISO9001: 2000.

Q: Which Countries are Your Beverage Machinery Sold to?

A: Our products are widely exported to U.S.A, Russia, England, Canada, Japan, Egypt, Mexico, South Africa, North Korea, Indonesia, Mongolia, Malaysia, Dominica, Nigeria, Libya, Turkey, Kazakstan, Iran, Yemen, Sudan, Vietnam, Bengal, Burma, Serbia, Macedonia, Lebanon, Congo, Syria, Venezuela, Iraq, Saudi Arabia, and Kenya.

Q: What Kind of After-sale Services does Your Company Provide?

A: Installation guides, device debugging and technical trainings are offered to our global customers to help them make full use of our water production lines, tea filling machines, beverage production lines, and other beverage machinery.

TAG: 380V Automatic Conveyor System Conveyor System Heavy duty auto conveyor system Heavy duty automatic conveyor system

-

WhatsApp/Tel : +8613915693104

-

Email : [email protected]

-

Email : [email protected]

-

Address : Machinery Industry Park of Jinfeng Town, Suzhou City, Jiangsu, China

© 2023 HZM Machinery Co., Ltd. All Rights Reserved

Submitted successfully

We have received your message and will get in touch with you as soon as possible to provide you with the corresponding service

Home /

Home /