Beverage Five In One 500ml PET Bottle Aseptic Filling Line

| Material: | Stainless Steel | Process: | Aseptic Filling System |

|---|---|---|---|

| Certification: | GB/T19001-2000 | Type: | Filling Machine |

| Applicable Products: | Water, Aerated Soda Water, Cola, Sprite, Aerated Juice | Capacity Range: | 15000 Bottles/hour ----36000 Bottles/hour (500ml) |

| Filling Valve: | Adopt Imported Flow Meter Valve According To Customer Demand | Applicable: | PET Bottle |

| High Light: | 500ml PET Bottle Aseptic Filling Line, 500ml Five In One Aseptic Filling Line, 500ml Aseptic Beverage Filling Line | ||

Beverage Five In One 500ml PET Bottle Aseptic Filling Line

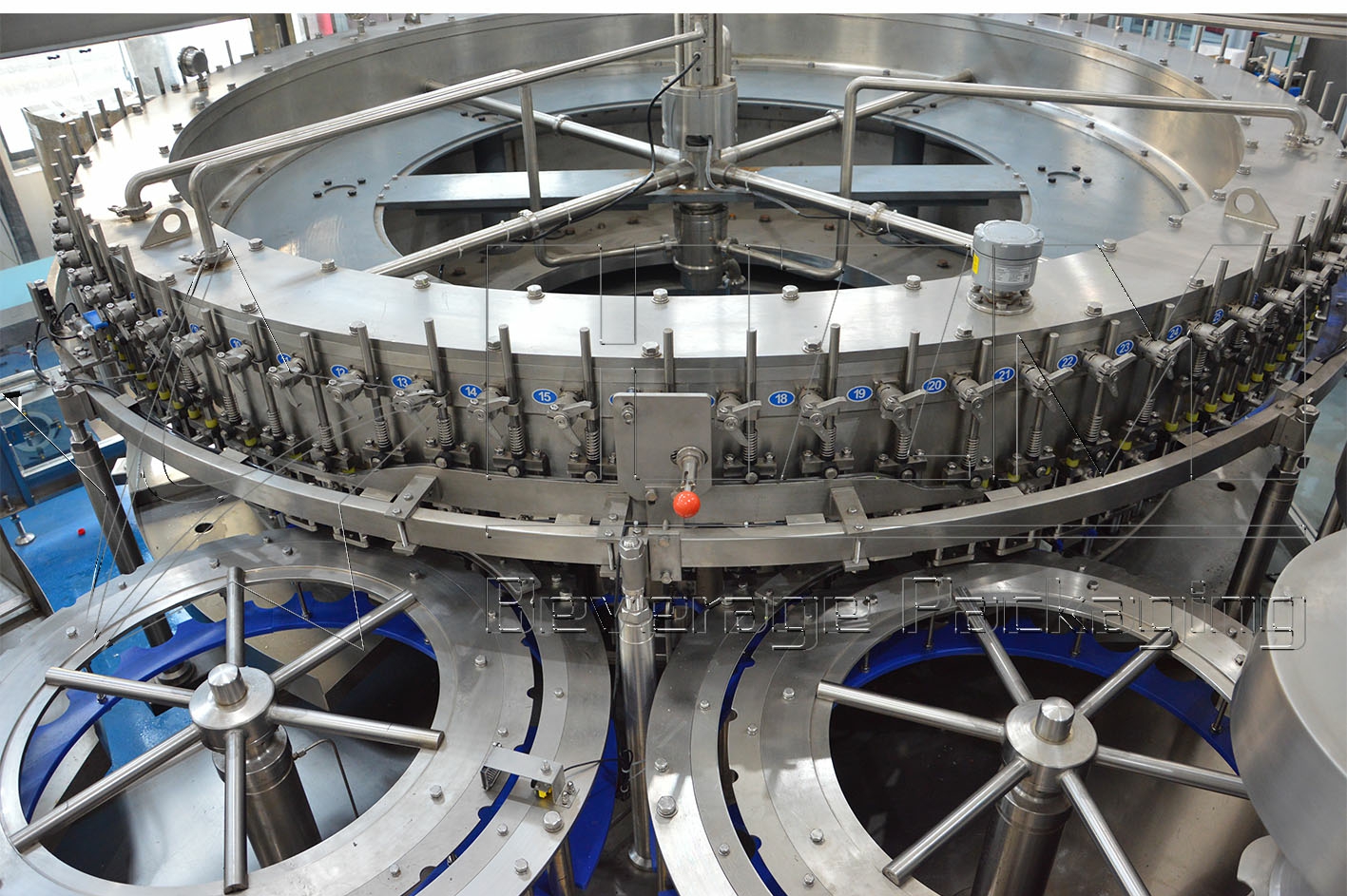

The Aseptic Beverage Filling Line Is A Kind Of Five In One PET Bottle Filling Line

Suitable for high-end aerated mineral water, aerated soda water, cola, sprite, aerated juice

Capacity: 15000 bottles/hour ----36000 bottles/hour (500ml) Applicable bottle types 200ml-1500ml

Filling valve: adopt imported flow meter valve according to customer demand

The aseptic beverage filling line is a five-in-one PET bottle filling line. It is designed and manufactured based on aseptic filling technology. The automatic aseptic filling line is suitable for bottles with a diameter of 55 to 105mm and a height of 186 to 325mm. Beverage filling equipment is suitable for all kinds of beverages and juices, with an hourly production rate of 12,000-24,000 bottles (500 ml).

|

Material |

Stainless steel |

|

Process |

Pressure filling system |

|

Certification |

GB/T19001-2000 |

|

Type |

Filling Machine |

|

Applicable products |

water, aerated soda water, cola, sprite, aerated juice |

|

Capacity range |

15000 bottles/hour ---36000 bottles/hour (500ml) |

|

Filling valve |

adopt imported flow meter valve according to customer demand |

|

Applicable |

PET bottle |

Technical features:

The six-valve blowing valve group, three blowing and two recycling energy-saving solutions, enable customers to save energy by more than 25%.

Customer-customized full servo stretching system to meet various stretch ratios.

Complete and fully automatic CIP, SIP, COP, SOP systems ensure the sanitary requirements of the inner and outer surfaces of the equipment.

Complete aseptic isolation system to ensure aseptic filling environment.

Adopt PROFIBUS intelligent control technology to realize the whole line control, intelligent data report, and real-time monitoring of all links.

Imported ion dust removal system to ensure the safety of packaging.

Customers can customize imported AROL capping system.

As a aseptic cold filling line manufacturer with over 10 years of experience, we at HZM can provide customers quality built products at a smart price. In order to ensure each customers find the product their require, we also provide other beverage production line, including water production line, juice production line, tea drink production line etc. Because our products are reliable, durable and economical, they are CE certified and are in great demand by customers from the USA, Canada, Indonesia, Kenya, Egypt, Japan, among other countries.

FAQ

Q: What are the Primary Products of Your Company?

A: Our products mainly include water production line, juice production line, tea production line, water filling machine, juice filling machine, tea filling machine, and more.

Q: Where is Your Beverage Machinery Applied to?

A: Our beverage production lines are extensively used for packaging of water, fruit juice, tea drinks, milk beverage, juice with grains, sodas, protein beverages, energy drinks, and more.

Q: What are the Properties of Your Beverage Production Lines?

A: Our beverage machinery adopts automatic operation system which greatly improves the performance and productivity of our packaging machines. They have properties of multifunction, standard design, modularization, digital control system, good compatibility, high accuracy, flexibility, and high working efficiency.

All these measures together enable us to provide high quality carbonated beverage production lines, can filling machines, juice production lines, tea filling machines, etc, at competitive prices.

Q: Do Your Water Production Lines Meet Environmental Protection Requirements?

A: Our water production lines are eco-friendly and energy-saving. They adopt advanced environmental protection technologies from Germany and Italy. All production procedures quite meet the standards of ISO9001: 2000.

Q: What Kind of After-sale Services does Your Company Provide?

A: Installation guides, device debugging and technical trainings are offered to our global customers to help them make full use of our water production lines, tea filling machines, beverage production lines, and other beverage machinery.

TAG: 500ml Aseptic Beverage Filling Line 500ml Five In One Aseptic Filling Line 500ml PET Bottle Aseptic Filling Line Aseptic Cold Filling Machine

-

![16000-36000bph Combi Block Aseptic Blowing Filling Capping For PET Bottle]() 16000-36000bph Combi Block Aseptic Blowing Filling Capping For PET BottleJun , 09 /2023

16000-36000bph Combi Block Aseptic Blowing Filling Capping For PET BottleJun , 09 /2023 -

![5 In 1 SS Aseptic Bottle Filler For High End Aerated Juice]() 5 In 1 SS Aseptic Bottle Filler For High End Aerated JuiceJun , 09 /2023

5 In 1 SS Aseptic Bottle Filler For High End Aerated JuiceJun , 09 /2023 -

![Aerated Soda Water 40000 BPH Aseptic Cold Filling Line]() Aerated Soda Water 40000 BPH Aseptic Cold Filling LineJun , 09 /2023

Aerated Soda Water 40000 BPH Aseptic Cold Filling LineJun , 09 /2023 -

![PET Bottle 200ml 1500ml Aseptic Liquid Filling Machine]() PET Bottle 200ml 1500ml Aseptic Liquid Filling MachineJun , 09 /2023

PET Bottle 200ml 1500ml Aseptic Liquid Filling MachineJun , 09 /2023

Home /

Home /