Beer Production Line 200ml Carbonated Soft Drink Filling Machine

| Material: | Stainless Steel And Non-toxic Materials | Process: | Isobaric Pressure Filling System |

|---|---|---|---|

| Certification: | GB/T19001-2000 | Type: | Filling Machine |

| Filling Principle: | Equal Pressure Filling | Capacity: | 8000 Bottles/hour -54000 Bottles/hour (500ml) |

| Applicable Bottle Type: | 200ml-1500ml | Function: | Carbonated Soft Drink Filling Machine |

| High Light: | 200ml Carbonated Soft Drink Filling Machine, 200ml Beer Production Line, 54000 BPH Carbonated Soft Drink Filling Machine | ||

Beer Production Line 200ml Carbonated Soft Drink Filling Machine

Carbonated Beverage Production Line , Beer Production Line

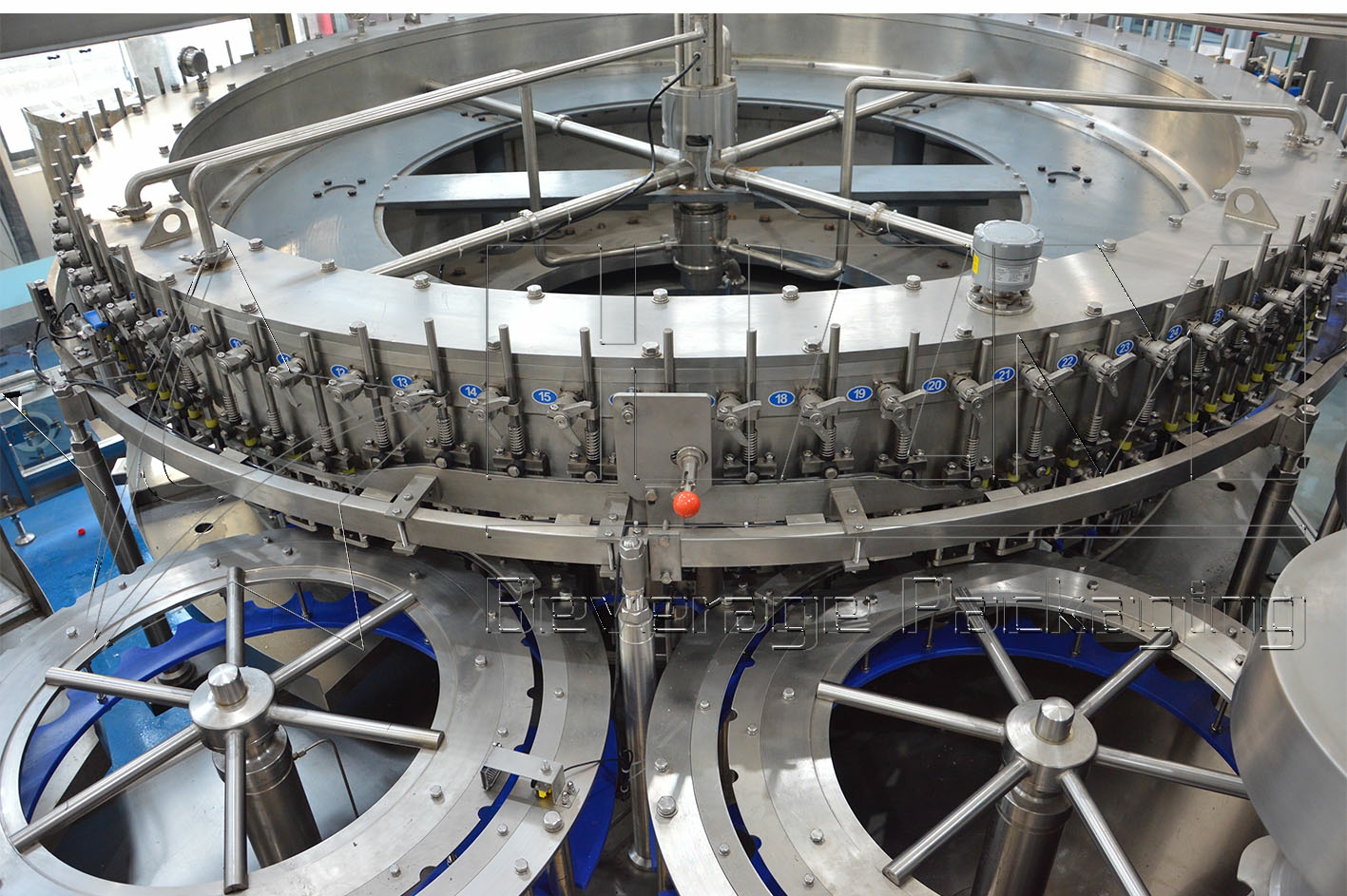

DGP series rinser-filler-capper, which perfectly combines bottle rinsing machine, filling machine and capping machine together in one unit, is an high efficient liquid packing machine designed for packing both carbonated drinks and non-carbonated drinks such as juice and water.

As a quality conscious carbonated beverage production line and beer production line manufacturer in China, we at HZM have been dedicated to producing high quality beverage production lines since our foundation. Through decades of experience and continued efforts of our highly trained staff, now we can provide global customers with superior products at affordable prices. Some of our popular products are juice production lines, tea drink production lines, water filling machines, and blow molding machines. As our products are CE certified, you can feel at ease in using them.

Specifications of Carbonated Filling Machine

| Model | Number of Bottle Rinsing Clip | Number of Filling Valve | Number of Capping Head | Capacity (BPH) |

Bottle Size |

Outline Dimensions(mm) | Weight (Kg) | Remark | ||

| Diameter (mm) | Height (mm) | Volume (ml) | ||||||||

| DGP06 | 18 | 18 | 6 | 5000-6000 | Φ60-Φ96 | 180-315 | 350-1500 | 2480x1980x2600 | 4000 | All-in-one Type |

| DGP08 | 24 | 24 | 8 | 6000-10000 | Φ60-Φ96 | 180-315 | 350-1500 | 2800x2400x2600 | 6000 | All-in-one Type |

| DGP10 | 32 | 32 | 10 | 10000-14000 | Φ60-Φ96 | 180-315 | 350-1500 | 3300x3000x2700 25002500 3085 | 7200 | Split Type |

| DGP12 | 40 | 40 | 12 | 14000-18000 | Φ60-Φ96 | 180-315 | 350-1500 | 3900x3180x2700 | 9000 | Split Type |

| DGP15 | 50 | 50 | 15 | 18000-20000 | Φ60-Φ96 | 180-315 | 350-1500 | 5300x4200x2900 | 10000 | Split Type |

| DGP15 | 60 | 60 | 15 | 20000-24000 | Φ60-Φ96 | 180-315 | 350-1500 | 5700x4600x2900 | 12000 | Split Type |

| DGP18 | 72 | 72 | 18 | 22000-28000 | Φ60-Φ96 | 180-315 | 350-1500 | 6600x5100x2900 | 15000 | Split Type |

Features

1. All parts in contact with liquid are made out of superior stainless steel or nontoxic material to ensure food safety and hygiene, typically, the filling valves are made of stainless steed 316.

2. The airproof parts are made of heat resistant rubber, thus meeting the high temperature requirement for sterilization.

3. Our carbonated beverage, beer production line adopts PLC system and thus full automatic control is achieved.

4. The frequency conversion control for motor speed makes equipment adjustment more convenient.

5. The adoption of the isobaric filling method and the use of the popular spring filling valve ensure the quality of the drinks.

6. The utilization of advanced magnetic clutch device and adjustable capping torque results in good capping quality.

Application

High-end aerated mineral water, aerated soda, cola, sprite, aerated juice

TAG: 200ml Beer Production Line 200ml Carbonated Soft Drink Filling Machine 54000 BPH Carbonated Soft Drink Filling Machine Carbonated Soft Drink Filling Machine

-

![28000 BPH SS316 Carbonated Soft Drink Filling Machine For Sale]() 28000 BPH SS316 Carbonated Soft Drink Filling Machine For SaleJun , 09 /2023

28000 BPH SS316 Carbonated Soft Drink Filling Machine For SaleJun , 09 /2023 -

![High End Aerated 8000 BPH Soda Filling And Capping Machine]() High End Aerated 8000 BPH Soda Filling And Capping MachineJun , 09 /2023

High End Aerated 8000 BPH Soda Filling And Capping MachineJun , 09 /2023 -

![Equal Pressure 24000 BPH Carbonated Soft Drink Filling Machine]() Equal Pressure 24000 BPH Carbonated Soft Drink Filling MachineJun , 09 /2023

Equal Pressure 24000 BPH Carbonated Soft Drink Filling MachineJun , 09 /2023 -

![PLC Non Toxic 200ml Carbonated Soft Drink Filling Machine]() PLC Non Toxic 200ml Carbonated Soft Drink Filling MachineJun , 09 /2023

PLC Non Toxic 200ml Carbonated Soft Drink Filling MachineJun , 09 /2023

Home /

Home /