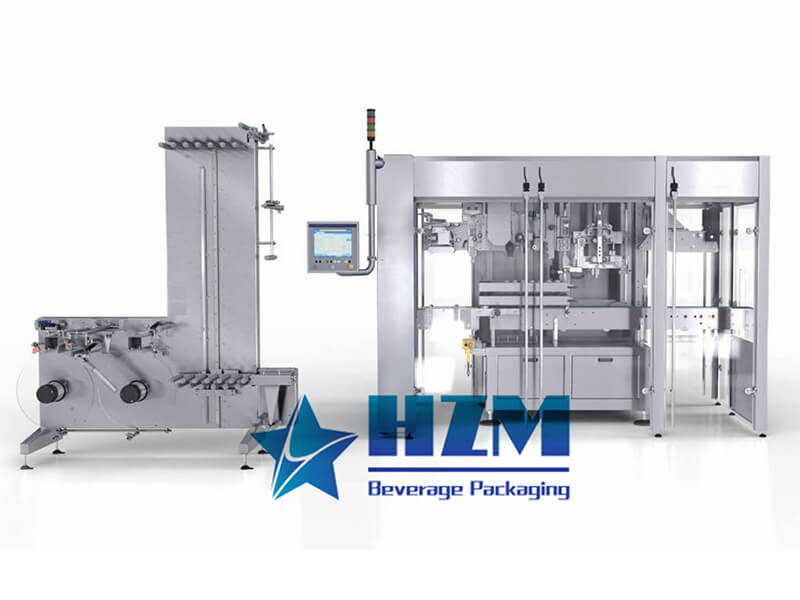

Automatic Water Bottle Sleeve Labeling Machine

The Automatic Water Bottle Sleeve Labeling Machine finds its application in a wide range of scenarios, particularly within industries that rely heavily on packaging. It caters to water bottling companies, beverage producers, cosmetics manufacturers, and even pharmaceutical firms. Its versatility enables it to accommodate various bottle shapes, sizes, and materials, ensuring a seamless fit for different product lines.

Key Features

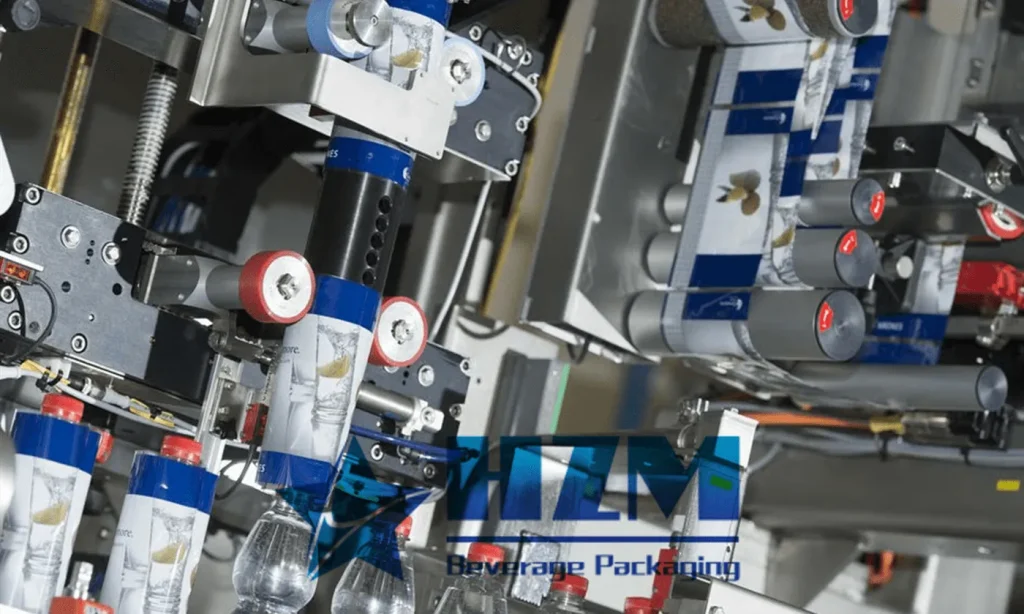

- Precision Sleeve Labeling: The machine's advanced technology guarantees accurate and consistent sleeve labeling. Its high-precision sensors ensure labels are applied seamlessly, even at high production speeds.

- Adaptability: Regardless of the bottle's curvature or material, this machine excels. It can handle glass, plastic, or metal containers, making it an ideal choice for businesses with diverse product ranges.

- Efficiency: Automation is the core of this machine. It streamlines the labeling process, enhancing production rates while minimizing human errors.

- User-Friendly Interface: Equipped with an intuitive interface, operators can easily input settings, monitor progress, and troubleshoot any issues swiftly.

- Space Optimization: The machine's compact design ensures it can be seamlessly integrated into existing production lines, optimizing floor space utilization.

Operational Principles

The machine's operation revolves around a sophisticated interplay of components. Bottles are fed onto a conveyor, which transports them through a series of stations. In these stations, labels are precisely cut and shaped to fit the bottles. Heat is then applied to shrink the labels, creating a snug, visually appealing fit. This entire process occurs rapidly, guaranteeing minimal disruption to production flow.

Maintenance and Care

To ensure the longevity and consistent performance of the Automatic Water Bottle Sleeve Labeling Machine, regular maintenance is imperative. This includes:

- Cleaning: Regularly cleaning the machine's components, conveyor, and label dispensing areas prevents label misplacement due to dirt or residue.

- Lubrication: Keeping moving parts well-lubricated minimizes friction and wear, sustaining optimal operational efficiency.

- Inspection: Routinely inspecting the sensors, heating elements, and electrical connections helps identify and rectify potential issues before they escalate.

- Calibration: Regularly calibrating the machine guarantees accurate label placement and prevents misalignment.

In conclusion, the Automatic Water Bottle Sleeve Labeling Machine represents a transformative leap in packaging technology. Its adaptability, precision, and efficiency make it a cornerstone of modern manufacturing processes, revolutionizing the way products are labeled. For industries seeking to elevate their branding and operational efficiency, investing in this automated solution proves to be a strategic decision. Regular maintenance ensures it remains a dependable asset, contributing to seamless production for years to come.

Home /

Home /