Choosing a High-Quality Automatic Sleeve Labeling Machine

With the development of global markets and advancements in technology, automatic sleeve labeling machines have become increasingly important in the packaging industry. As efficient, precise, and reliable equipment, selecting a high-quality automatic sleeve labeling machine is crucial for enhancing production efficiency and product quality. This article will discuss key factors to consider when choosing a high-quality automatic sleeve labeling machine to assist you in making informed decisions.

- Equipment Brand and Reputation: Selecting a well-known brand and reputable manufacturer of automatic sleeve labeling machines is the primary step in ensuring high quality. These manufacturers typically possess extensive experience and technical expertise, and are committed to continuous improvement and innovation. By choosing a reputable brand, you can ensure that you are purchasing equipment that has undergone rigorous testing and quality control.

- Technical Specifications and Features: When selecting an automatic sleeve labeling machine, carefully consider whether its technical specifications and features meet your requirements. Key technical specifications include labeling speed, accuracy, and the range of applicable label sizes. Additionally, automatic sleeve labeling machines may offer additional features such as automatic adjustment, automatic fault detection, and traceability systems. Ensure that the chosen equipment possesses the necessary technical specifications and features to accommodate your production needs.

- Material Quality and Structural Design: The material quality and structural design of an automatic sleeve labeling machine directly impact its lifespan and stability. High-quality automatic sleeve labeling machines typically utilize wear-resistant and corrosion-resistant materials, along with robust structural designs. Additionally, consider the equipment's ease of maintenance and cleanliness to ensure convenient daily upkeep and adherence to hygiene standards.

- Service and Support: Choosing a manufacturer that provides comprehensive after-sales service and support is a wise decision. Good after-sales service includes equipment installation and commissioning, operator training, regular maintenance, and prompt response to troubleshooting. Ensure that the manufacturer offers timely technical support and spare parts supply to minimize equipment downtime and production delays.

- References and Evaluations: Before finalizing the purchase of an automatic sleeve labeling machine, seeking references and evaluations from other users can be highly beneficial. You can read online forums, industry reviews, or consult with other companies that have experience with similar equipment. Gaining insights into the experiences and opinions of other users can help you comprehensively evaluate the performance and reliability of the equipment.

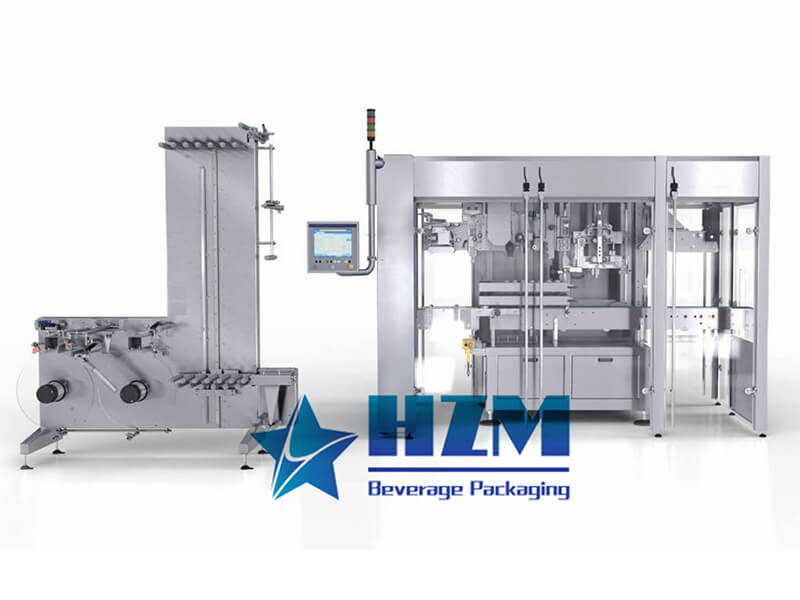

Conclusion: Choosing a high-quality automatic sleeve labeling machine is a critical step in improving production efficiency and product quality. By considering factors such as the equipment brand and reputation, technical specifications and features, material quality and structural design, service and support, as well as references and evaluations, you will be able to make informed decisions. Investing in a high-quality automatic sleeve labeling machine, such as the HZM, will provide long-term returns and a competitive edge to your business. The HZM brand ensures excellent equipment performance, reliability, and outstanding after-sales service, instilling confidence and efficiency in your production line.

-

![What is a sleeve labeling machine? How does it work?]() What is a sleeve labeling machine? How does it work?Mar , 24 /2023

What is a sleeve labeling machine? How does it work?Mar , 24 /2023 -

![Automatic Sleeve Labeling Machines Purchasing price]() Automatic Sleeve Labeling Machines Purchasing priceMay , 21 /2023

Automatic Sleeve Labeling Machines Purchasing priceMay , 21 /2023 -

![Revolutionizing Packaging Efficiency: The Power of Sleeve Labeling Machines]() Revolutionizing Packaging Efficiency: The Power of Sleeve Labeling MachinesJun , 16 /2023

Revolutionizing Packaging Efficiency: The Power of Sleeve Labeling MachinesJun , 16 /2023 -

![A Guide to Avoid Pitfalls When Purchasing an Automatic Sleeve Labeling Machine]() A Guide to Avoid Pitfalls When Purchasing an Automatic Sleeve Labeling MachineJun , 16 /2023

A Guide to Avoid Pitfalls When Purchasing an Automatic Sleeve Labeling MachineJun , 16 /2023

Home /

Home /