Automatic Drinking Water Filling Production Line Equipment

The equipment of the automatic drinking water filling production line has a wide range of applications in filling purified water, mineral water, drinking water, and PET bottled water. This production line equipment allows for the option of using metal anti-theft caps or plastic caps for sealing, making it an ideal choice for small and medium-sized beverage manufacturers. The automatic water filling machine utilizes OMRON programmable frequency converters (PLC) to control the automatic operation of the machine. The frequency control of the bottle inlet conveyor and the main machine work together to ensure a more stable and reliable bottle feeding process. The optical detection components of the purified water filling equipment achieve a high level of automation and are easy to operate. Additionally, the drinking water filling machine can also implement a low vacuum filling method by modifying the filling section.

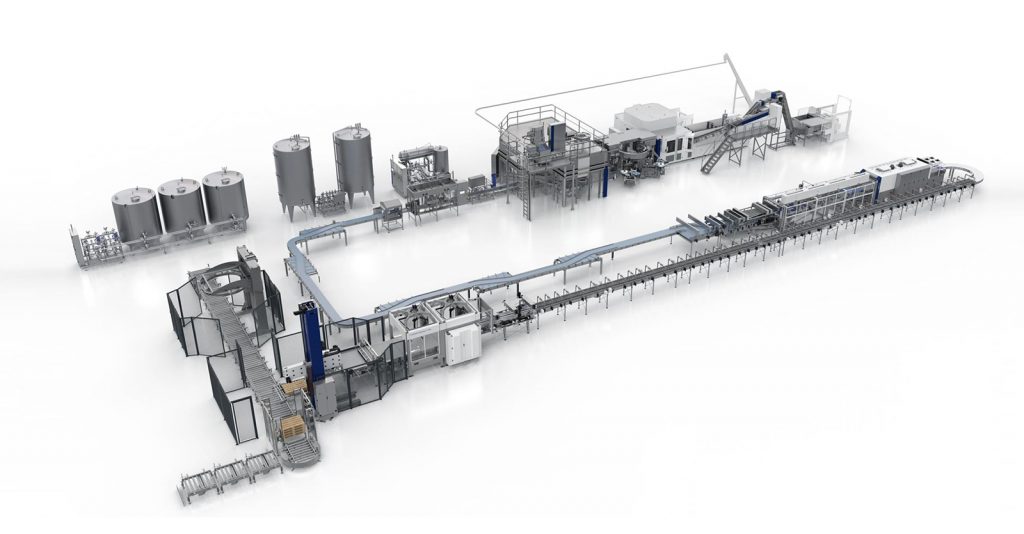

The equipment of the automatic drinking water filling production line mainly includes the following:

- Water treatment equipment: Water treatment equipment is used to treat and purify the raw water source to ensure the quality of drinking water meets the standards. It removes suspended solids, particles, bacteria, viruses, chemicals, and other impurities from the water, providing a clean water source for the subsequent filling process.

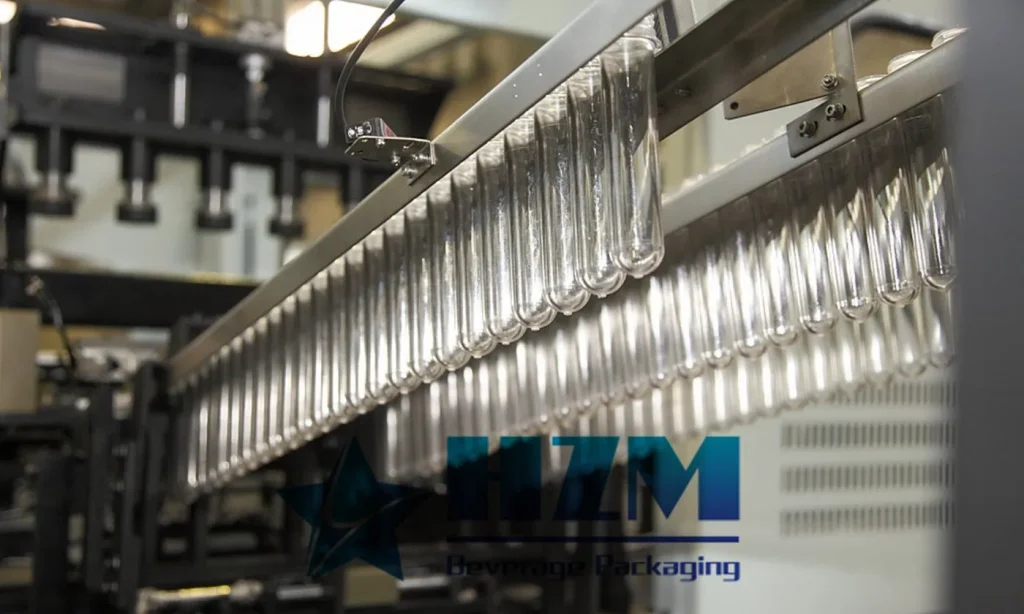

- Bottle blowing machine: The bottle blowing machine is used to thermally mold pre-made PET (Polyethylene Terephthalate) materials into hollow drinking water bottles. It heats the thermoplastic plastic to a pliable state and then expands it into the shape of a bottle through blowing air and mold forming.

- Tunnel-type Pasteurization Machine: Pasteurization is a common sterilization method used in the drinking water filling process. The tunnel-type pasteurization machine uses high-temperature steam to instantaneously heat and cool the bottles, achieving sterilization. It effectively kills microorganisms inside and outside the bottles, ensuring the hygiene and safety of drinking water.

- Automatic three-in-one filling machine: The three-in-one filling machine integrates bottle rinsing, filling, and sealing into one unit, serving as the core equipment of the drinking water filling line. It automatically completes bottle positioning, cleaning, filling with water, sealing, and discharge processes. The control system of the automatic three-in-one filling machine precisely controls the filling volume and speed to ensure that each bottle meets the preset standards.

- Bottle drying machine: The bottle drying machine is used to dry the filled drinking water bottles, removing water droplets from the surface of the bottles to ensure their cleanliness and appearance quality.

- Labeling machine: The labeling machine is responsible for applying labels to the outer surface of the drinking water bottles. It accurately positions and adheres labels to the bottles, providing them with brand identification and product information.

- Coding machine: The coding machine is used to print batch numbers, production dates, barcodes, and other information on the bottles. It efficiently and accurately applies codes based on preset parameters, facilitating product traceability and management.

- Film wrapping machine or carton packaging machine: Depending on the requirements, either a film wrapping machine or a carton packaging machine is used to package the filled drinking water bottles. The film wrapping machine wraps the bottles with plastic film to protect the product's safety and hygiene, while the carton packaging machine is used to place the bottled water into cartons for convenient storage and transportation.

- Palletizing machine: The palletizing machine is responsible for stacking and palletizing the packaged finished products, facilitating subsequent storage and distribution operations. It can stack bottles or packaging boxes in a neat and specified manner according to the set program.

In the automatic drinking water filling production line, each piece of equipment plays a different role and function. Through the collaboration and operation of these various equipment, the automatic drinking water filling production line achieves an automated and highly efficient production process, from the raw water source to the packaged finished products.

TAG: Labeling Machine PET Bottle Blowing Machine Water Bottle Filling Machine Water treatment system

-

![Plastic Bottle Blowing Machine, making machine]() Plastic Bottle Blowing Machine, making machine

Plastic Bottle Blowing Machine, making machine -

![Automatic Water Bottle Blowing Molding Machine]() Automatic Water Bottle Blowing Molding Machine

Automatic Water Bottle Blowing Molding Machine -

![Automatic Pure Water Bottling Filling Machine]() Automatic Pure Water Bottling Filling Machine

Automatic Pure Water Bottling Filling Machine -

![3-In-1 Water Bottle Filling Machine]() 3-In-1 Water Bottle Filling Machine

3-In-1 Water Bottle Filling Machine -

![Automatic Mineral Water Bottle Filling Machine]() Automatic Mineral Water Bottle Filling Machine

Automatic Mineral Water Bottle Filling Machine -

![Automatic Water Bottle Filling Machine]() Automatic Water Bottle Filling Machine

Automatic Water Bottle Filling Machine -

![Automatic Self-Adhesive Labeling Machine]() Automatic Self-Adhesive Labeling Machine

Automatic Self-Adhesive Labeling Machine -

![Automatic BOPP Hot Glue Labeling Machine]() Automatic BOPP Hot Glue Labeling Machine

Automatic BOPP Hot Glue Labeling Machine -

![Automatic Linear Type Hot Glue Labeling Machine]() Automatic Linear Type Hot Glue Labeling Machine

Automatic Linear Type Hot Glue Labeling Machine -

![Automatic Sleeve Labeling Machine]() Automatic Sleeve Labeling Machine

Automatic Sleeve Labeling Machine -

![Automatic Oil Bottle Wide Neck PET Bottle Blowing Machine]() Automatic Oil Bottle Wide Neck PET Bottle Blowing Machine

Automatic Oil Bottle Wide Neck PET Bottle Blowing Machine -

![Industrial Drinking Water Treatment System]() Industrial Drinking Water Treatment System

Industrial Drinking Water Treatment System -

![Water Treatment Machine Purification System]() Water Treatment Machine Purification System

Water Treatment Machine Purification System -

![Water Treatment System]() Water Treatment System

Water Treatment System

-

![Here are five things to consider for maintaining a fully automated mineral water production line]() Here are five things to consider for maintaining a fully automated mineral water production lineApr , 20 /2023

Here are five things to consider for maintaining a fully automated mineral water production lineApr , 20 /2023 -

![Drinking Water Treatment System Manufacturer and Solutions]() Drinking Water Treatment System Manufacturer and SolutionsMay , 05 /2023

Drinking Water Treatment System Manufacturer and SolutionsMay , 05 /2023 -

![How Do Label Machines Work?]() How Do Label Machines Work?Jun , 01 /2023

How Do Label Machines Work?Jun , 01 /2023 -

![Mineral Water / Soft Drink PET Bottle Machine Production Equipment]() Mineral Water / Soft Drink PET Bottle Machine Production EquipmentJun , 06 /2023

Mineral Water / Soft Drink PET Bottle Machine Production EquipmentJun , 06 /2023 -

![Stainless Steel 200ml Automatic Water Bottle Filling System]() Stainless Steel 200ml Automatic Water Bottle Filling SystemJun , 09 /2023

Stainless Steel 200ml Automatic Water Bottle Filling SystemJun , 09 /2023 -

![PET Bottle Blowing Machine: Leading Packaging Production Equipment]() PET Bottle Blowing Machine: Leading Packaging Production EquipmentJun , 17 /2023

PET Bottle Blowing Machine: Leading Packaging Production EquipmentJun , 17 /2023 -

![Key Factors for Choosing a High-Quality PET Bottle Blowing Machine]() Key Factors for Choosing a High-Quality PET Bottle Blowing MachineJun , 18 /2023

Key Factors for Choosing a High-Quality PET Bottle Blowing MachineJun , 18 /2023 -

![How to Avoid Pitfalls When Purchasing a PET Bottle Blowing Machine]() How to Avoid Pitfalls When Purchasing a PET Bottle Blowing MachineJun , 20 /2023

How to Avoid Pitfalls When Purchasing a PET Bottle Blowing MachineJun , 20 /2023 -

![Bottled Water Production Line:5-gallon]() Bottled Water Production Line:5-gallonJun , 23 /2023

Bottled Water Production Line:5-gallonJun , 23 /2023 -

![In-Depth Analysis of the Water Bottle Filling Machine Market]() In-Depth Analysis of the Water Bottle Filling Machine MarketJun , 28 /2023

In-Depth Analysis of the Water Bottle Filling Machine MarketJun , 28 /2023 -

![Design, Installation, Commissioning, Production, and Maintenance of a Water Bottle Filling Line]() Design, Installation, Commissioning, Production, and Maintenance of a Water Bottle Filling LineJun , 29 /2023

Design, Installation, Commissioning, Production, and Maintenance of a Water Bottle Filling LineJun , 29 /2023 -

![Mineral Water Production Line Equipment: Prices and Manufacturers]() Mineral Water Production Line Equipment: Prices and ManufacturersJun , 30 /2023

Mineral Water Production Line Equipment: Prices and ManufacturersJun , 30 /2023 -

![How to create a complete Water Filling Line?]() How to create a complete Water Filling Line?Jul , 10 /2023

How to create a complete Water Filling Line?Jul , 10 /2023 -

![Full Automatic Glass Bottle Alcohol Vodka Liquor Wine Bottling Filling Capping Labeling Machine]() Full Automatic Glass Bottle Alcohol Vodka Liquor Wine Bottling Filling Capping Labeling MachineAug , 22 /2023

Full Automatic Glass Bottle Alcohol Vodka Liquor Wine Bottling Filling Capping Labeling MachineAug , 22 /2023 -

![Bottled water production process PDF]() Bottled water production process PDFSep , 18 /2023

Bottled water production process PDFSep , 18 /2023 -

![Automatic 150BPM Sleeve Shrink Labeling Machine]() Automatic 150BPM Sleeve Shrink Labeling MachineNov , 03 /2023

Automatic 150BPM Sleeve Shrink Labeling MachineNov , 03 /2023

Home /

Home /