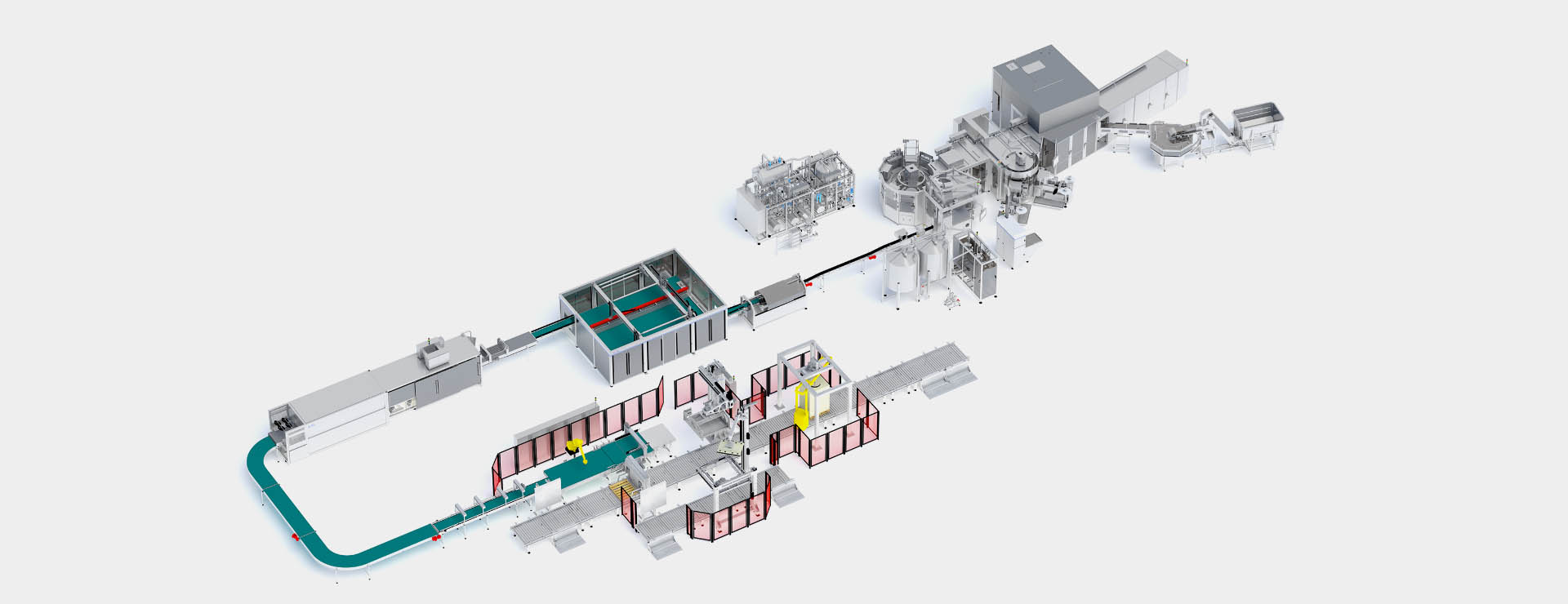

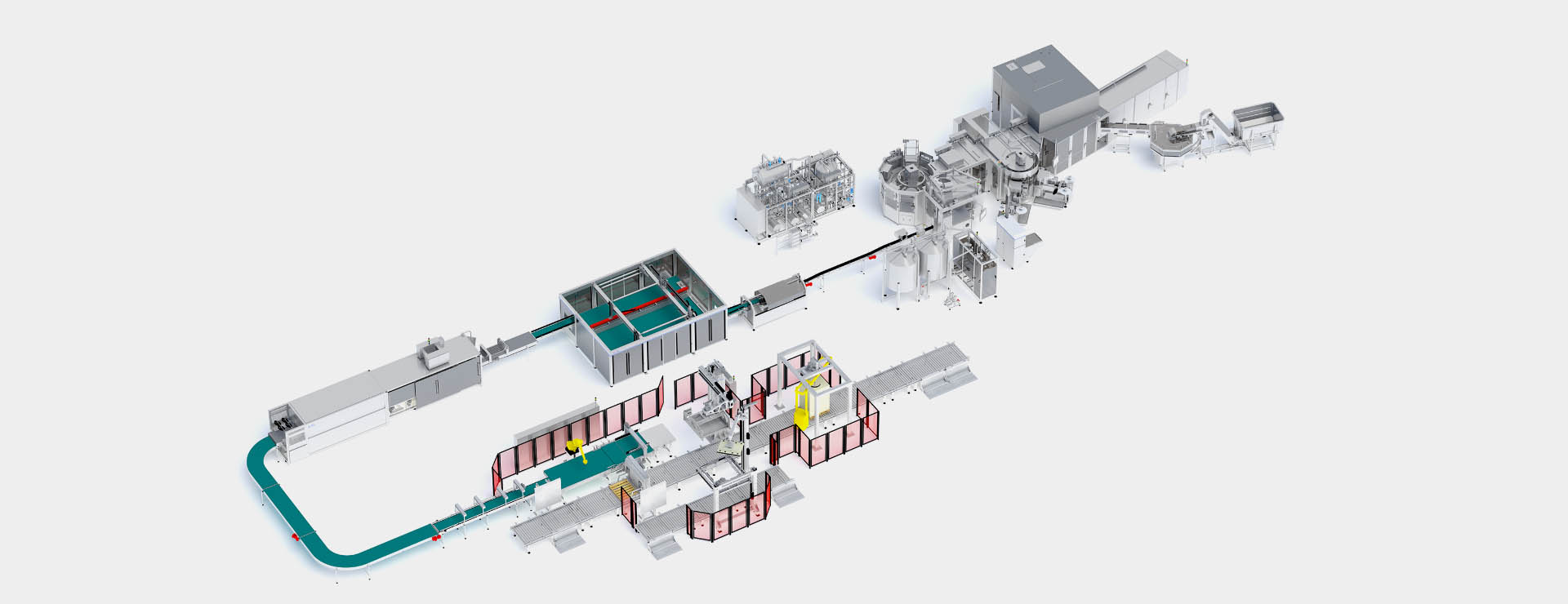

Automated Production Line for Carbonated Beverages: 36,000 Bottles Per Hour

In the rapidly evolving food industry, automated production lines have become a crucial factor in enhancing production efficiency and quality. Especially in the domain of carbonated beverage production, automated lines play an irreplaceable role. Today, we will delve into an automated production line capable of producing 36,000 bottles of carbonated beverages per hour.

I. Overview of the Production Line

The design and manufacturing of this carbonated beverage automated production line take into account multiple aspects such as production efficiency, product quality, and production costs. Through highly automated equipment and systems, the entire process from raw material input to product packaging is automated.

II. Key Equipment and Processes

- Raw Material Feeding System: This system can automatically introduce raw materials into the production equipment in predetermined proportions and sequences, significantly improving the accuracy and efficiency of raw material input.

- Syrup Blending System: This system precisely blends syrup and other additives according to preset recipes to ensure consistent taste and product quality.

- Carbonation System: In this system, syrup and carbon dioxide are mixed in specified ratios to create the distinctive flavor of carbonated beverages.

- Bottling and Sealing System: The carbonated beverage, after mixing, is filled into pre-cleaned bottles and sealed using a sealing machine to ensure product sealing and hygiene.

- Quality Inspection System: At the end of the production line, there is a quality inspection stage that rigorously examines each bottle of beverage to ensure product quality meets the standards.

III. Production Efficiency and Costs

The ability to produce 36,000 bottles of carbonated beverages per hour significantly boosts production efficiency while maintaining product quality. Furthermore, through automated production, labor costs and error rates can be reduced, further enhancing production efficiency.

IV. Future Development Trends

With advancements in technology and evolving consumer demands, future automated production lines for carbonated beverages will become more intelligent and efficient. For example, by incorporating more advanced sensors and data analytics technology, real-time monitoring and optimization of the production process can be achieved. By adopting advanced packaging materials and techniques, product freshness and eco-friendliness can be improved. The integration of the Internet of Things (IoT) and artificial intelligence technology can enable remote control and smart management of the production line.

Moreover, as consumer awareness of healthy eating continues to grow, future automated production lines for carbonated beverages will focus more on the nutritional value and natural ingredients of products. For instance, using natural sweeteners instead of artificial ones and substituting synthetic dyes with natural pigments rich in antioxidants.

In summary, the automated production line capable of producing 36,000 bottles of carbonated beverages per hour represents a significant direction in the food industry's development. By continually improving production efficiency, product quality, reducing production costs, and increasing product value, such production lines will have a greater advantage in future market competition. As consumers, we can look forward to more high-quality, healthy, and delicious carbonated beverages in our lives.

TAG: Carbonated Beverage Filling Machine carbonated beverage production line Carbonated Drinks Filling Machine

-

![Core Selling Points of Glass Bottle CSD Filling & Capping Line]()

Core Selling Points of Glass Bottle CSD Filling & Capping Line

-

![Customizable beverage filling system]()

Customizable beverage filling system

-

![Differences Between Hot Filling and Cold Filling in Beverage Filling Machines]()

Differences Between Hot Filling and Cold Filling in Beverage Filling Machines

-

![Selecting a Dedicated RO Reverse Osmosis Water Treatment System for a Purified Water Beverage Production Line]()

Selecting a Dedicated RO Reverse Osmosis Water Treatment System for a Purified Water Beverage Production Line

-

![How Fast Is the Labeling Speed of Tea Beverage Packaging Machines?]()

How Fast Is the Labeling Speed of Tea Beverage Packaging Machines?