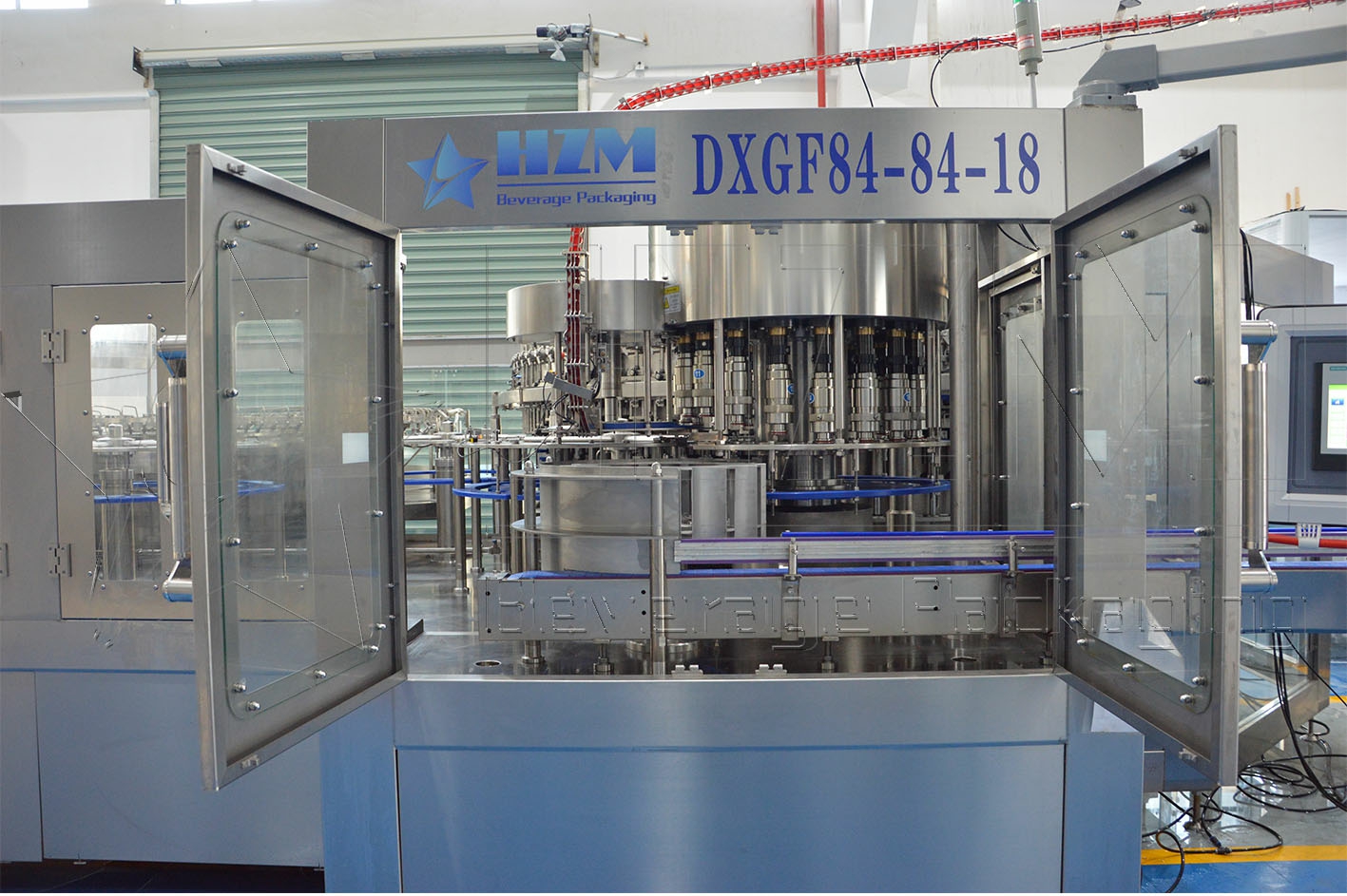

380V 50HZ Fully Automatic Blow Moulding Machine For Pet Bottle

| Model: | BCP-8B | Bottle Volume: | 300-1500mm |

|---|---|---|---|

| Production Capacity: | 16000b/h | Length Of Preform: | 50-160mm |

| Diameter Of Bottle: | 35-110mm | Height Of Bottle: | 120-330mm |

| Dimensions Of Machine: | 7100×4000×3980mm | Weight Of Machine: | 12000kg |

| Blowing Pressure: | 3.5-4.0Mpa | Working Pressure: | 0.8-1.0Mpa |

| Using Voltage: | 380V.50HZ | Installed Power: | 168kw |

| Actual Power: | 80Kw | Mould Cooling: | 30HP |

| Lubrication Standard: | 35-60# | ||

| High Light: | Fully Automatic Blow Moulding Machine, 50HZ Blow Moulding Machine, 380V Blow Molding Machine | ||

380V 50HZ Fully Automatic Blow Moulding Machine For Pet Bottle

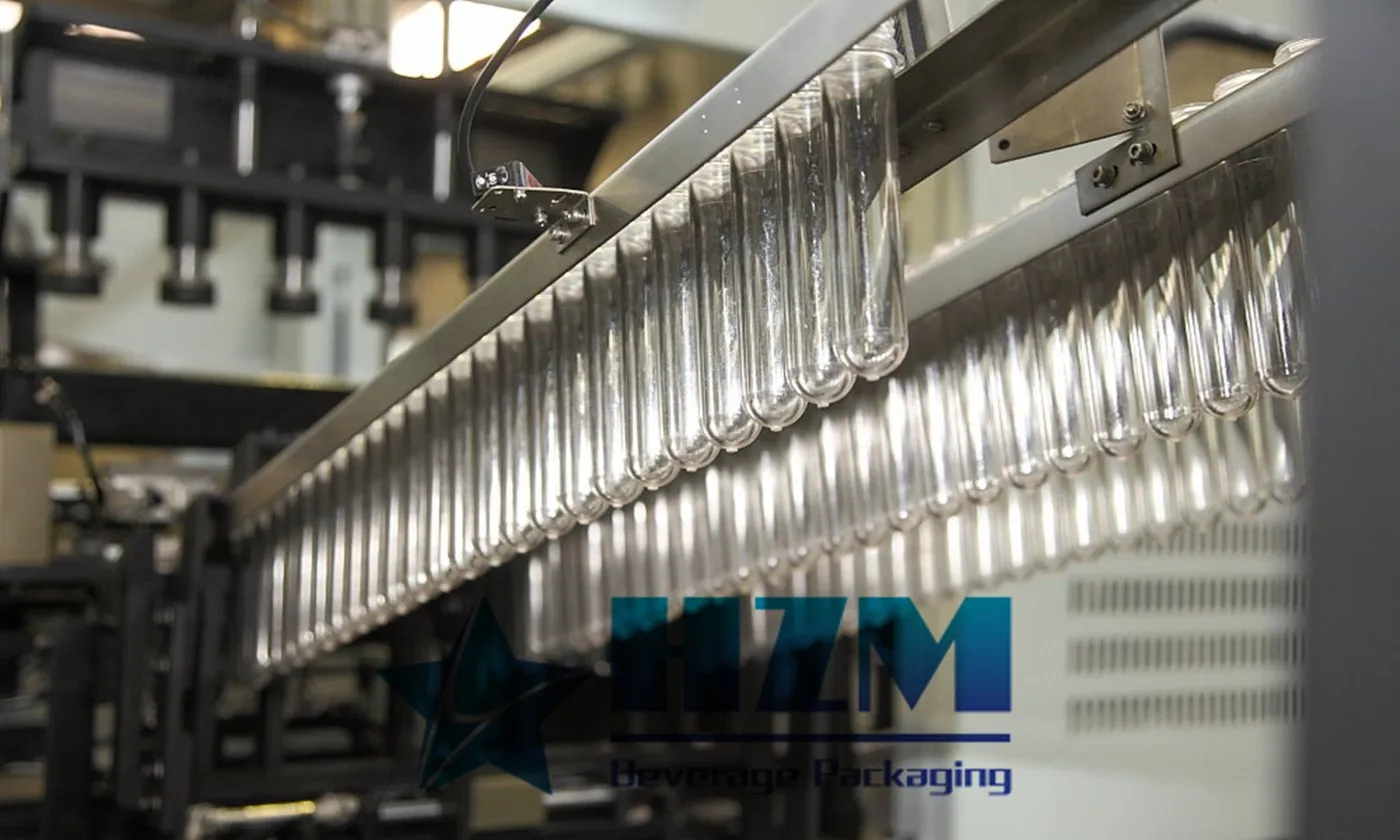

Automatic PET Blow Molding Machine

Our BCP series automatic PET blow molding machine is designed and manufactured according to our decades of experience, and the production capacity is from 15000 to 48000B/H. It has the advantages of convenient setting, ergonomic design, high efficiency, simple operation and strong flexibility. In addition, our PET blow molding machine can be customized according to customers' specific requirements. As an experienced blow molding machine manufacturer in China, Baiguan Group provides customers with training and maintenance services to ensure the smooth operation of our products.

Features:

- Three-blowing and two-recovery energy-saving technology: pressure difference cascade use, saving compressed air and energy about 40%.

- Mechanical sealing safeguard technology: The sealing track ensures that the sealing cylinder is raised quickly and absolutely, which is mainly used to ensure the safety of the high-speed blowing machine.

- Pre-blowing proportional valve control technology: The operation panel controls more precise process guarantees and energy saving measures.

- Manipulator fork automatic clamping technology: the manipulator fork automatically opens and clamps the bottle mouth, so as to ensure that the bottle or preforms is more stable and not scratched.

- Heating and ventilation independent module: improve the modularization, general utilization and standardization, realize the module inlay technology, easy to install, maintain and adjust the process.

- Servo stretching technology: it can quickly and accurately control the up and down moving speed and position of the stretching rod, realizing that stretch bottles of various height specifications by the same stretching rod, meet the stretching requirements of various preforms and solve the problem that some preforms are not easy to stretch.

- Heating lamp monitoring technology: real-time monitoring of heating lamps in each zone and layer of the heating oven, and interconnection with the operation panel, which can quickly and accurately check the use of heating lamps in each zone and layer of the heating oven.

- Cooling water circuit temperature inspection technology: real-time inspection of the cooling water inlet temperature, interconnection with the operation panel, data visualization, and accurate adjustment of the cooling water temperature according to the cooling effect of different bottle types.

- High-speed, silent, low-consumption, artware

Specifications of Rotary Blow Molding Machine

| Item | BCP-8B | BCP-10B | BCP-12B | BCP-14B |

| Bottle Volume Range | 300-1500ml | 300-1500mm | 300-1500mm | 300-1500mm |

| Production Capacity | 16000BPH (500ml) | 20000BPH (500ml) | 24000BPH (500ml) | 28000BPH (500ml) |

| Max Diameter of Bottle | 110mm | 110mm | 110mm | 110mm |

| Max Height of Bottle | 330mm | 330mm | 330mm | 330mm |

| Dimensions of Machine | 7100×4000×3980mm | 7100×4000×3980mm | 7100×4000×3980mm | 7500×4200×3980mm |

| Weight of Machine | 12000kg | 13400kg | 16300kg | 18000kg |

| Blowing Pressure | 3.5-4.0Mpa | 3.5-4.0Mpa | 3.5-4.0Mpa | 3.5-4.0Mpa |

| Air consumption | 5m3/min | 6m3/min | 8m3/min | 9m3/min |

| Using Voltage | 380V.50HZ | 380V.50HZ | 380V.50HZ | 380V.50HZ |

| Installed Power | 168kw | 206kw | 244Kw | 244Kw |

| Average energy consumption | 80Kw | 100Kw | 120Kw | 120Kw |

| Mould Cooling | 30HP | 30HP | 35 HP | 35HP |

| Available Material | PET | PET | PET | PET |

Applications

Our automatic PET blow molding machine is suitable for use as water bottle molding machine, oil bottle moulding machine, juice bottle molding machine, and others.

During our consistent efforts over the past decades, we at BestCrown are able to provide a wide array of water production line, beverage filling machine and auxiliary equipment of beverage machinery. Some of our popular products are bottled water production line, carbonated beverage filling machine, can production line, and more. These products are reliable, durable, economical and CE certified. Thus, they are well received in many countries, including the USA, Canada, Britain, Russia, Japan, Egypt, South Africa, among others.

Certificates

1. Our beverage machinery is approved as qualified products for seven years by Chinese beverage industry association.

2. Our company is approved as excellent supplier of filling equipment four times by Chinese beverage industry association.

3. Our company is entitled "Star Enterprise" by Chinese food and packaging machinery industry association.

4. Our company is approved as the enterprise technical center of Zhangjiagang Province.

5. Our company obtains ISO9001:2000 International Quality Management System Certification.

6. Our company is awarded as demonstration enterprise of national CAD application engineering by Ministry of Science and Technology of China.

7. All our products are awarded as CE certification.

8. Our company becomes the vice chairman of Chinese food and packaging machinery industry association.

TAG: 380V Blow Molding Machine 50HZ Blow Moulding Machine Blow Molding Machine Fully Automatic Blow Moulding Machine

-

![Successful Delivery of New Blow Molding Machine to Indonesian Customer]() Successful Delivery of New Blow Molding Machine to Indonesian CustomerMar , 24 /2023

Successful Delivery of New Blow Molding Machine to Indonesian CustomerMar , 24 /2023 -

![The Edible Oil Bottle Blowing Machine: Unveiling Efficiency and Precision]() The Edible Oil Bottle Blowing Machine: Unveiling Efficiency and PrecisionMay , 12 /2023

The Edible Oil Bottle Blowing Machine: Unveiling Efficiency and PrecisionMay , 12 /2023 -

![Automatic Rotary Blow Molding Machine: Features, Applications, and Maintenance]() Automatic Rotary Blow Molding Machine: Features, Applications, and MaintenanceMay , 12 /2023

Automatic Rotary Blow Molding Machine: Features, Applications, and MaintenanceMay , 12 /2023 -

![Maintenance and Care of 5 Gallon Bottle Blow Molding Machine]() Maintenance and Care of 5 Gallon Bottle Blow Molding MachineJun , 06 /2023

Maintenance and Care of 5 Gallon Bottle Blow Molding MachineJun , 06 /2023

Home /

Home /