3-in-1 Beverage Filling Machine: Combining Bottle Washing, Filling, and Capping

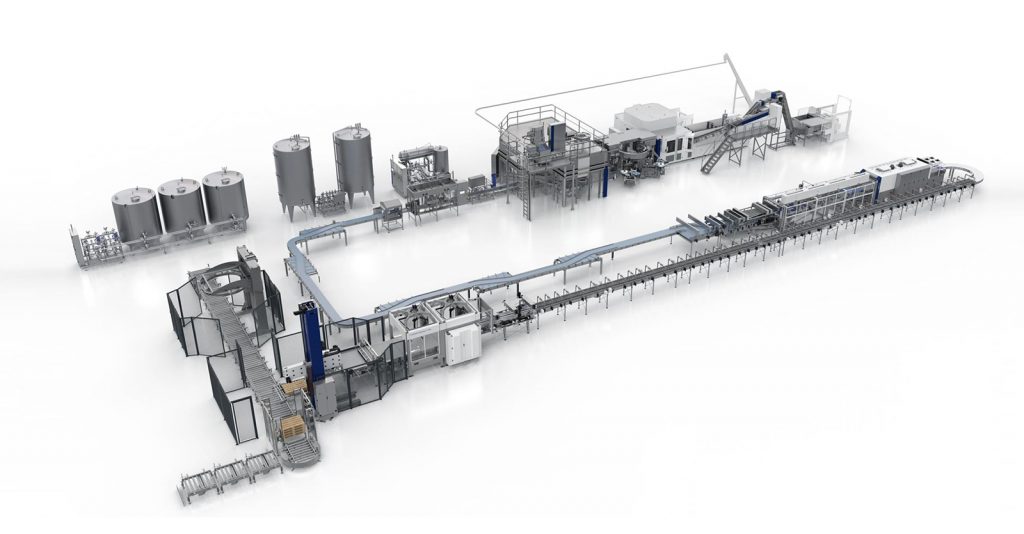

A 3-in-1 beverage filling machine is an efficient automated device that integrates three crucial steps in the beverage production process: bottle washing, filling, and capping. Here is a detailed introduction to the three-in-one beverage filling machine:

1. Bottle Washing: The first step in the three-in-one beverage filling machine is bottle washing. This process is carried out using an efficient bottle washing system to ensure the cleanliness and hygiene of both the inside and outside surfaces of the bottles. This is essential for maintaining the quality and safety of the beverage, especially in the case of reusable glass or PET bottles.

2. Beverage Filling: Following bottle washing, the three-in-one beverage filling machine accurately fills each bottle with the beverage. This step can accommodate various types of beverages, including fruit juices, carbonated drinks, dairy products, and more. The machine's design makes the filling process highly automated, capable of handling a large volume of bottles, ensuring beverage consistency and accuracy.

3. Capping: The final step involves securely capping or sealing the bottles to prevent beverage spillage and external contamination during transportation and storage. The capping system of the three-in-one beverage filling machine can accommodate different types of caps, from screw caps to snap-on caps, to meet the requirements of various beverages.

The primary advantages of the three-in-one beverage filling machine include:

- Efficiency: By integrating the three essential steps, it reduces the need for bottle transfer and waiting times, enhancing production efficiency.

- Space-saving: The three-in-one machine has a relatively small footprint, making it suitable for production environments with limited space.

- Hygiene and Quality: Through automated bottle washing and filling processes, it ensures the hygiene and quality of the beverages.

- Accuracy: The machine precisely controls the filling quantity, reducing waste and product variability.

- Versatility: It is suitable for different types of beverages and bottles, providing flexibility.

The three-in-one beverage filling machine plays a critical role in the beverage production industry, offering high levels of automation and convenience, helping businesses meet market demands, improve production efficiency, and ensure product quality and safety.

TAG: Beverage Filling Machine Water Bottle Filling Machine

-

![Automatic Pure Water Bottling Filling Machine]() Automatic Pure Water Bottling Filling Machine

Automatic Pure Water Bottling Filling Machine -

![3-In-1 Water Bottle Filling Machine]() 3-In-1 Water Bottle Filling Machine

3-In-1 Water Bottle Filling Machine -

![Automatic Mineral Water Bottle Filling Machine]() Automatic Mineral Water Bottle Filling Machine

Automatic Mineral Water Bottle Filling Machine -

![PET Bottle CSD Beverage Filling Machine]() PET Bottle CSD Beverage Filling Machine

PET Bottle CSD Beverage Filling Machine -

![Glass Bottle CSD Beverage Filling Machine]() Glass Bottle CSD Beverage Filling Machine

Glass Bottle CSD Beverage Filling Machine -

![CSD Beverage Can Filling Machine]() CSD Beverage Can Filling Machine

CSD Beverage Can Filling Machine -

![Carbonated Drinks Filling Machine]() Carbonated Drinks Filling Machine

Carbonated Drinks Filling Machine -

![Automatic Water Bottle Filling Machine]() Automatic Water Bottle Filling Machine

Automatic Water Bottle Filling Machine

-

![Important Questions To Consider Before Purchasing Carbonated Filling Machine]() Important Questions To Consider Before Purchasing Carbonated Filling MachineFeb , 19 /2023

Important Questions To Consider Before Purchasing Carbonated Filling MachineFeb , 19 /2023 -

![Classification of beverage filling machines]() Classification of beverage filling machinesMar , 24 /2023

Classification of beverage filling machinesMar , 24 /2023 -

![Complete Installation and Commission DXGF40-40-10 Carbonated Beverage Filling Machine]() Complete Installation and Commission DXGF40-40-10 Carbonated Beverage Filling MachineApr , 18 /2023

Complete Installation and Commission DXGF40-40-10 Carbonated Beverage Filling MachineApr , 18 /2023 -

![Application of Juice Beverage Filling Machine in the Industry]() Application of Juice Beverage Filling Machine in the IndustryApr , 25 /2023

Application of Juice Beverage Filling Machine in the IndustryApr , 25 /2023 -

![Stainless Steel 200ml Automatic Water Bottle Filling System]() Stainless Steel 200ml Automatic Water Bottle Filling SystemJun , 09 /2023

Stainless Steel 200ml Automatic Water Bottle Filling SystemJun , 09 /2023 -

![Bottled Water Production Line:5-gallon]() Bottled Water Production Line:5-gallonJun , 23 /2023

Bottled Water Production Line:5-gallonJun , 23 /2023 -

![In-Depth Analysis of the Water Bottle Filling Machine Market]() In-Depth Analysis of the Water Bottle Filling Machine MarketJun , 28 /2023

In-Depth Analysis of the Water Bottle Filling Machine MarketJun , 28 /2023 -

![Design, Installation, Commissioning, Production, and Maintenance of a Water Bottle Filling Line]() Design, Installation, Commissioning, Production, and Maintenance of a Water Bottle Filling LineJun , 29 /2023

Design, Installation, Commissioning, Production, and Maintenance of a Water Bottle Filling LineJun , 29 /2023

Home /

Home /