24000 bpm Aseptic Cold Filling Machine For Beverage Drinks For Sale

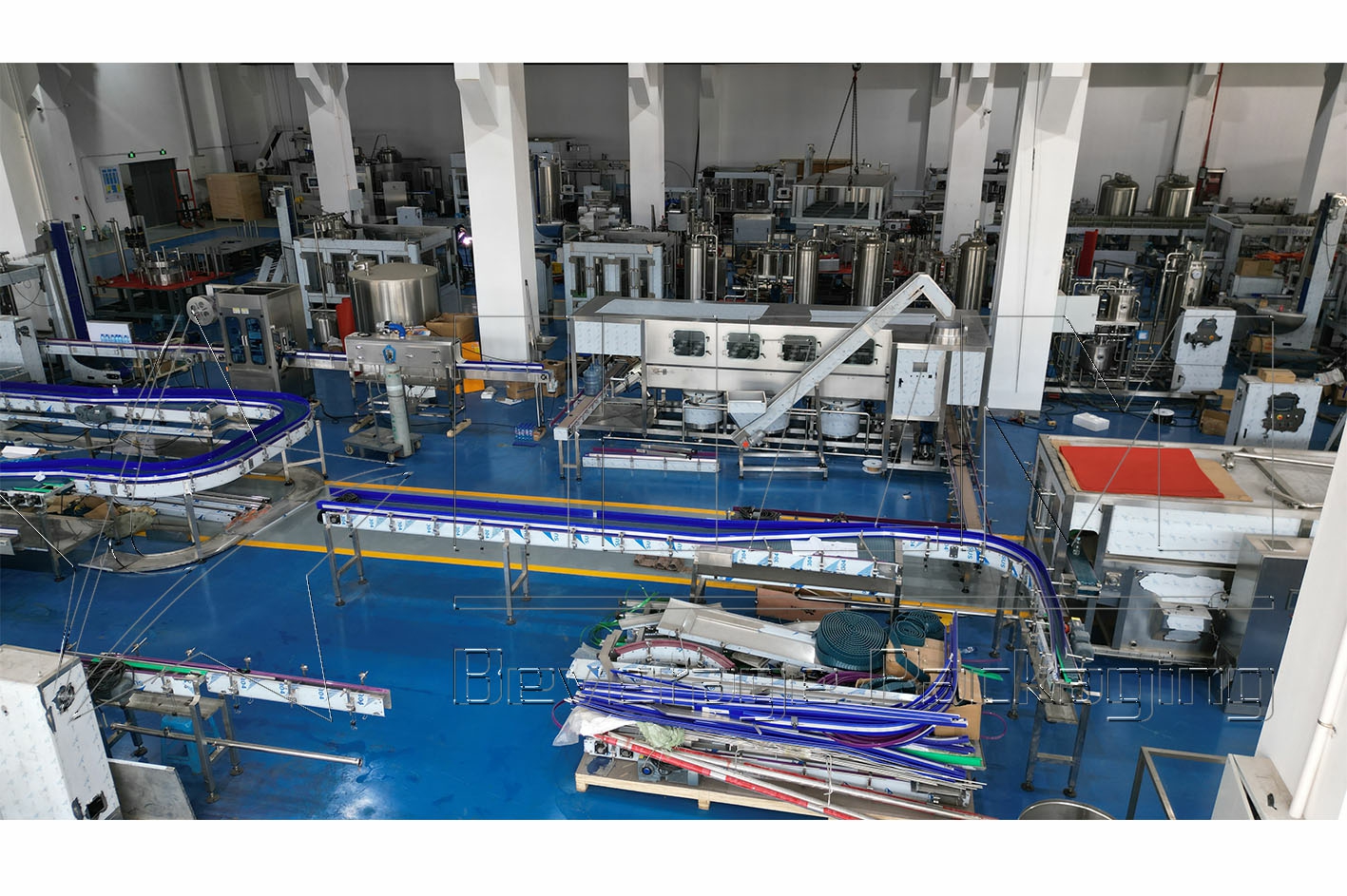

For sale: High-quality 24000 bpm Aseptic Cold Filling Machine for Beverage Drinks from China. Leading in the 24000 bpm Aseptic Cold Filling Machine category, it undergoes strict quality control in our facilities. Trust in excellence with our top-notch 24000 bpm aseptic bottle filling machine.

24000 bpm Aseptic Cold Filling Machine For Beverage Drinks Parameter

| Material: | Stainless Steel | Name: | Aseptic Bottle Filling Machine |

|---|---|---|---|

| Applicable Products: | Fruit Juice, Tea Drinks, Protein Drinks, Dairy Products, Etc. | Filling Valve: | Adopt Imported Flow Meter Valve/imported Electronic Weighing Valve According To Customer Needs |

| Model: | GWJX06A / GWJX15A | Number Of Bottle Dumping Clip: | 24 / 72 |

| Number Of Bottle Rinsing Clip: | 24 / 60 | Number Of Filling Valve: | 24 / 60 |

| Number Of Capping Head: | 8 / 15 | Capacity (BPH): | 15000 - 36000 |

| Bottle Volume (ml): | 350-1500 | Outline Dimensions (mm): | 7100x 2860x 3000 / 11900 X8500x 3200 |

| Quality (Kg): | 10000 / 25000 | Remark: | Split Type |

| High Light: | 24000 bpm Aseptic Cold Filling Machine, Split Aseptic Cold Filling Machine, 24000 bpm aseptic bottle filling machine | ||

PET bottled beverage aseptic cold filling machine

Aseptic cold filling production line adopts aseptic isolation technology to ensure the sterilization of filling materials, packaging environment and packaging containers. The bottle caps are sterilized using a reliable sterilization method to ensure the sterility of the empty caps.

The quantitative measurement of the patented filling valve adopts the international advanced electronic weighing system, which greatly improves the filling accuracy and leads the field of aseptic filling. PROFIBUS bus control technology is adopted to realize communication and full-line control between each machine, online display of full-line operation status and fault alarm, greatly improving the level of automatic control and reducing the possibility of human error operation.

Specifications of Bottled Water Filling Machine

| Model | Number of Bottle Dumping Clip | Number of Bottle Rinsing Clip | Number of Filling Valve | Number of Capping Head | Capacity (BPH) | Bottle Size | Outline Dimensions (mm) | Quality (Kg) | Remark | ||

| Diameter (mm) | Height (mm) | Volume (ml) | |||||||||

| GWJX06A | 24 | 24 | 24 | 8 | 2500(2.5L) | Φ60-Φ115 | 180-315 | 350-1500 | 7100x 2860x 3000 | 10000 | Split Type |

| GWJX15A | 72 | 60 | 60 | 15 | 24000(500ml) | Φ60-Φ96 | 180-315 | 350-1500 | 11900 x8500x 3200 | 25000 | Split Type |

Features

Our aseptic cold filling line is modularly constructed for great flexibility. It combines the dumping machine, rinser, filler and capper into one unit, and the part above the table-board is full closed by shielding can.

The imported electronic weighing sensor of filling valve ensures high measuring precision and makes it convenient to adjust product variety.

Automatic control of CIP and SIP operations is realized.

The inside of of pipeline and valve in contact with material meets the related sanitation standard.

Certificates

1. Our beverage machinery is approved as qualified products for seven years by Chinese beverage industry association.

2. Our company is approved as excellent supplier of filling equipment four times by Chinese beverage industry association.

3. Our company is entitled "Star Enterprise" by Chinese food and packaging machinery industry association.

4. Our company is approved as the enterprise technical center of Zhangjiagang Province.

5. Our company obtains ISO9001:2000 International Quality Management System Certification.

6. Our company is awarded as demonstration enterprise of national CAD application engineering by Ministry of Science and Technology of China.

7. All our products are awarded as CE certification.

8. Our company becomes the vice chairman of Chinese food and packaging machinery industry association.

FAQ

Q: What are the Primary Products of Your Company?

A: Our products mainly include water production line, juice production line, tea production line, water filling machine, juice filling machine, tea filling machine, and more.

Q: Where is Your Beverage Machinery Applied to?

A: Our beverage production lines are extensively used for packaging of water, fruit juice, tea drinks, milk beverage, juice with grains, sodas, protein beverages, energy drinks, and more.

Q: What are the Properties of Your Beverage Production Lines?

A: Our beverage machinery adopts automatic operation system which greatly improves the performance and productivity of our packaging machines. They have properties of multifunction, standard design, modularization, digital control system, good compatibility, high accuracy, flexibility, and high working efficiency.

All these measures together enable us to provide high quality carbonated beverage production lines, can filling machines, juice production lines, tea filling machines, etc, at competitive prices.

Q: Do Your Water Production Lines Meet Environmental Protection Requirements?

A: Our water production lines are eco-friendly and energy-saving. They adopt advanced environmental protection technologies from Germany and Italy. All production procedures quite meet the standards of ISO9001: 2000.

Q: Which Countries are Your Beverage Machinery Sold to?

A: Our products are widely exported to U.S.A, Russia, England, Canada, Japan, Egypt, Mexico, South Africa, North Korea, Indonesia, Mongolia, Malaysia, Dominica, Nigeria, Libya, Turkey, Kazakstan, Iran, Yemen, Sudan, Vietnam, Bengal, Burma, Serbia, Macedonia, Lebanon, Congo, Syria, Venezuela, Iraq, Saudi Arabia, and Kenya.

Q: What Kind of After-sale Services does Your Company Provide?

A: Installation guides, device debugging and technical trainings are offered to our global customers to help them make full use of our water production lines, tea filling machines, beverage production lines, and other beverage machinery.

TAG: Aseptic Filling Machine Beverage Filling Machines

-

![Classification of beverage filling machines]() Classification of beverage filling machinesMar , 24 /2023

Classification of beverage filling machinesMar , 24 /2023 -

![Beverage opens the era of diversified consumption]() Beverage opens the era of diversified consumptionMar , 24 /2023

Beverage opens the era of diversified consumptionMar , 24 /2023 -

![Fully Understanding Automatic Beverage Filling Machines]() Fully Understanding Automatic Beverage Filling MachinesMay , 08 /2023

Fully Understanding Automatic Beverage Filling MachinesMay , 08 /2023 -

![How to Properly Maintain and Service Automatic Beverage Packaging Machines]() How to Properly Maintain and Service Automatic Beverage Packaging MachinesMay , 17 /2023

How to Properly Maintain and Service Automatic Beverage Packaging MachinesMay , 17 /2023 -

![15000bph Liquid Cold Intelligent Aseptic Filling Equipment For Sale]() 15000bph Liquid Cold Intelligent Aseptic Filling Equipment For SaleJun , 09 /2023

15000bph Liquid Cold Intelligent Aseptic Filling Equipment For SaleJun , 09 /2023 -

![60-Valve Dry Aseptic Filling Machine]() 60-Valve Dry Aseptic Filling MachineJun , 09 /2023

60-Valve Dry Aseptic Filling MachineJun , 09 /2023

Home /

Home /